Unicelium

Designing a world beyond waste by developing a circular packaging solution made of biomaterials.

Project Information

Client Collaboration between Virtuo Labs, Kono NZ LP (Kono) and BioFab

Industry Consumer Products, Food & Beverage Innovation

Services Environmental Innovation

Key Outcomes

Mapped problematic areas and impact hotspots.

Identified a series of new utilisation opportunities for the company's waste.

Designed circular material flows that worked within operational force factors.

Developed new material applications for grapemarc and mussel shells .

Create a new way to package seafood using these materials.

Overview

Develop a circular packaging solution to meet Kono’s sustainability targets of being waste free by 2030, which in turn lead to the creation of a new product value system for the company.

Kono, a vertically integrated, family-owned Māori food and beverage producer, needed help achieving its goal of becoming waste-free and reducing the organization's impact on the environment. Kono was also looking to explore ways to turn waste generated through its operations into new opportunities that would preserve and enhance our taonga for the benefit of current and future generations.

Frame

New Zealand’s decision to ban single use plastics by 2025 has lead many companies to rethink how to minimise their packaging and waste, seeking more natural alternatives.

Working collaboratively with Kono, we posed the question: can we replace existing synthetic materials such as polystyrene and film wrap to reduce waste consumption with natural biomaterials? How might we implement a new material or packaging solution into a business's production and supply chain with as little disruption as possible - to replace the synthetic materials currently used? Kono had set its strategic vision on becoming waste-free by 2030.

The answer was one of purpose: to preserve and enhance our taonga for the benefit of current and future generations. By utilizing waste materials that currently result from existing harvest and production processes, we set out to create a new packaging solution that can naturally protect products and safely decompose without damaging the environment.

Our Approach

We started by seeking to understand the problem areas for the company and the size of the environmental impacts that they posed. This exercise identified a series of waste material streams, including general plastics used in packaging and storage, mussel shells, apple pulp, and grapemarc. We then studied the unique attributes of these waste materials and began to understand how they could be repurposed.

While mapping the processing flows, it became clear what operational factors were the barriers to change. Understanding what needed to change, the team was inspired to see how the materials flowing out of the company's vertically integrated supply chain could be used to enhance the company's products. The inspiration was simple: how could we use Kono’s waste materials to create packaging, reducing waste and plastic?

The team came to understand that a novel product would need to be designed to replace plastic polystyrene for Kono's seafood products. This was a unique challenge because Kono exports perishable seafood all around the world, which requires specific temperatures and handling.

After in-depth research, we decided to approach the problem by processing grapemarc and mussel shells into a composite material that could be bound together with a natural binder. After proving the concept with partners Biofab, we began to design a material structure and packaging system that could meet the performance requirements.

Numerous processes and bioengineering solutions were explored to create a thermally insulation, structurally robust, moisture resistant and tear-proof material. The development team also wanted to provide a material universal in form with endless utilisation opportunities (a standard offering), and be able to easily apply the material to custom-makes. This involved developing new material processing methods to create and form the items. Getting the materials to fold and hinge was a large part of the journey.

The nature of creating packaging from this specific biomaterial offers unique possibilities. The ultimate package that was designed incorporated a natural seal detail, meaning the contents remained fresh until the customer opened the package (what the team internally titled as ‘nature’s fresh lock’).

Outcome

From defining key waste impact areas to rethinking packaging, this project developed a range of outcomes. Ultimately, it developed a pathway showing how it is possible for a well-established company to transition away from plastic packaging and in doing so reduce its waste by turning its waste materials (that already exist within its own processes) into the solution.

Unicelium is now a registered trademark. All rights reserved. If you are interested, please contact us for further details.

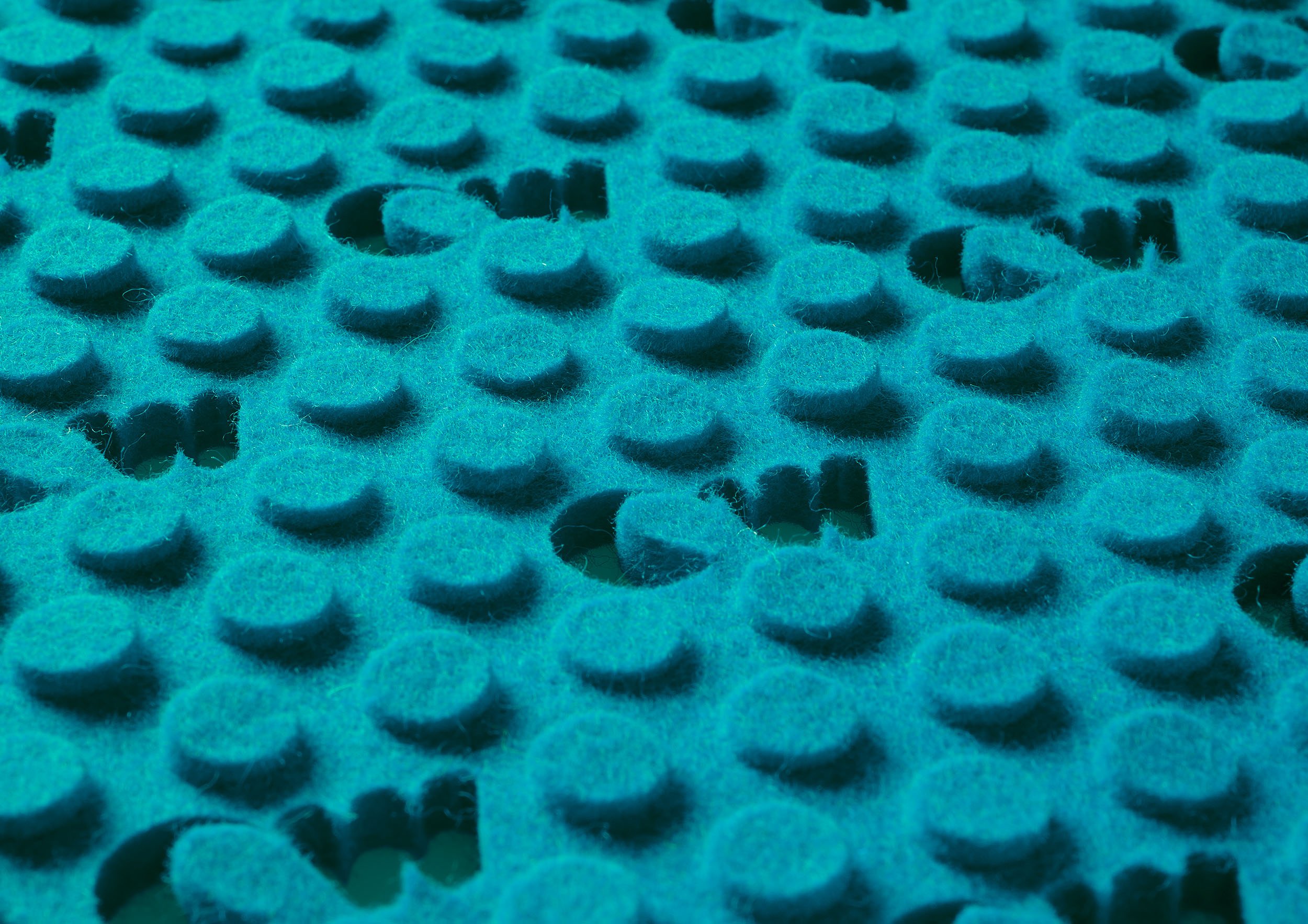

A NEW MYCELIUM FORM

Universal in form with endless utilisation opportunities

By utilizing compression bioengineering processes, we have developed robust tear-proof materials with patterns, flutes, and layered structures. This innovation is ideal for replacing common plastic sheets and allows mycelium to become a direct competitor to bubble wrap, thanks to the flexibility and mobility that the pattern provides.

ELEVATING THERMAL CONDITIONS

Water and moisture considerations

The use of a hybrid combination of biopolymers and our biomaterial technology ensures that seafood arrives at its destination fresh.

Ice indicators can be moulded onto the packaging for an accurate measure of ice depending on the arrival location.

Love for the land. Respect for the sea.

On creating a truly circular packaging system

Kono is determined to become waste-free by 2030. As a Māori food and beverage provider, designing a packaging lifecycle that aligns with their core values of Kataikitanga (our duty, our heritage, our legacy) was key to this project.

By creating a packaging system from a biomaterial that grows, we were able to solve one of the principal issues the project presented. By repurposing New Zealand's precious natural resources intergenerationally, we can ensure that what is taken from the land and sea can be safely returned.

The poetic beauty maintained in the design of each object ensures that Kono is offering a solution which truly represents their gift from the land and sea. Hua a te whenua me to moana.